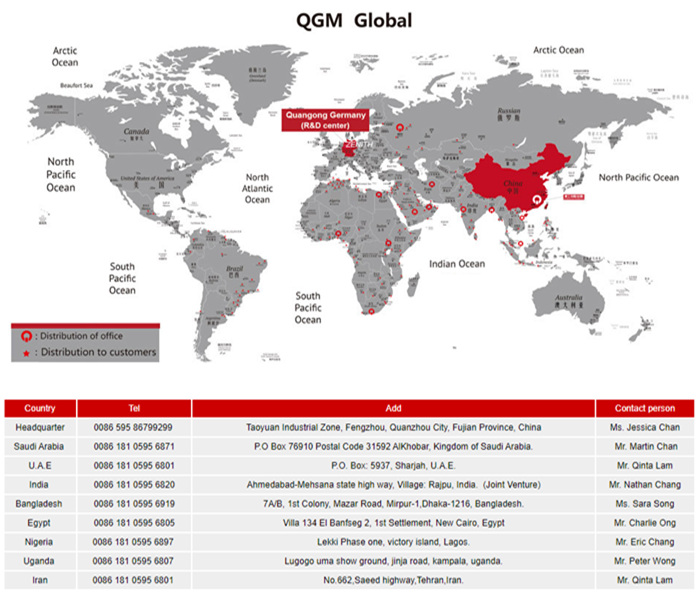

China Automatic Paver Block Making Machine Manufacture Suppliers

- QGM

- China

- 30-60 days

- 10 sets per month

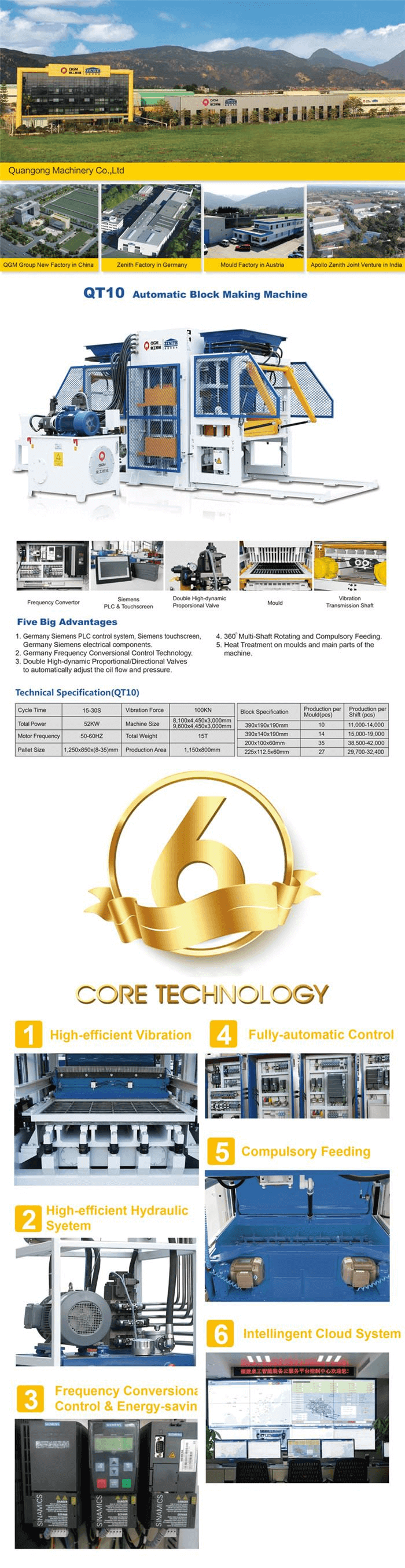

QT10 is an economical equipment, independently developed and produced by QGM, which can meet the diversified production needs of small enterprises and is cost-effective. It can produce various blocks, such as exterior wall blocks, interior wall blocks, flower wall blocks, floor slabs, river protection blocks, interlocks and curbstones. The secondary (topping)feeding cart can also produce colorful paver.

QGM QT10 is a reliable brick machine that has been sold to over 170 countries and places.

Most of the electronic components are from SIEMENS.Even the motors are from SIEMENS. They can start up with mild voltage. SIEMENS motors can reduce 30% waste of energy for your production.

The hydraulic station is made of two hydraulic pumps with a flange interface. Shorter cycle time with stronger pressure. The oil pipe is from Alphagoma. It also has a mechanical design to prevent damage from inertia.The vibration table is made of Hardox steel. The hardness reaches 55 HRC. It never breaks.

Applied Products: concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc.

Applied Fields: widely used in buildings, road pavings, squares, gardens, landscaping, city constructions.

Technical Parameters:

| Cycle Time | 15-25S |

| Total Power | 52KW |

| Motor Frequency | 50-60HZ |

| Vibration Force | 100KN |

| Total Weight | 15T |

| Brick Machine Size | 8,100x4,450x3,000mm |

| 9,600x4,450x3,000mm | |

| Production per Mould | (390x190x190mm)10 pcs/mould |

| (240x115x53mm)54 pcs/mould | |

| (200x100x60mm)35 pcs/mould | |

| Pallet size | 1,250×850mm |

| Production Capacity | (390x190x190mm) 14,000-19,920pcs |

| (200x100x60/80mm)40,320-50,000pcs |

BIG FIVE ADVANTAGES OF QGM QT10 AUTOMATIC BLOCK MAKING MACHINES:

Our machines, with harmonic cooperation between mechanical, electrical and hydraulic machines functions, guarantee a reliable and high output production of concrete products

1. Use Germany Siemens PLC control system and Siemens Touch Screen, use Schneider and Omron relays and contactors

Perfectly combine the automatic technology and systemfrom Germany.Adopt Germany SIEMENS PLC controlsystem, touch screen, through the effective combinationof digital and displacement sensing technology, all kindsof actions are accurate and reliable, computer controlsaves time and effort, easy operation and low failure ratio.The machinery is equipped with data inputloutput deviceand data formula function. Ilt can be used for permanentpreservation. The Control System for safety has logiccontrol with self-locking function, in order to protect themachinery from damaging because of operational error.

2. Use Frequency Conversional Control Technology, which controls the block making

Adopt the patented SIEMENS frequency conversionalcontrol technology from Germany, with features of energysaving and working stability.Adopt braking unit withresistor for turning off the machine in order to stop theexcess energy consumption, which can solve the problemof inertia when machine stops working. With precisepressure control capability and adjustable operatingspeed, which can save 20%-30% power, compare to thetraditional motor, and greatly improve the quality ofconcrete products and prolong the lifetime of motor.

3. Use Double high-dynamic Proportional/Directional Valves to automatically adjust the oil flow and pressure

The hydraulic control system adopts high-dynamicproportional valve and constant output pump,which arefrom international brand, to adjust the oil flow and pressure automatically, with the features of high-stability,high-efficiency and energy-saving.

4. 360° Multi-Shaft Rotating and Compulsory Feeding

A. Speedy and rotating feeding, with uniform mixing, to make sure that the density and intensity of the products are guaranteed

B. This uniform feeding is applicable for different kinds of raw materials and moulds.

5. Use heat treatment on moulds and main parts of the machines

A. Heavy duty machine structure and wear resistant moulds;

B. The hardness reaches up to HRC 52-58;

C. Greatly improves the using lifetime of the machine by 50%.