QGM New QT6 Block Machine Production Line Installed and Running Well in Morowali 2022

Background:

In December 2021, Mr.Andi (the GM of the company) decided to buy a new block making machine production line to expand their production scale.After they compared with a few block machine manufacturers around the world and finally they decided to buy the machine from QGM.They signed the sales contract for the automatic QGM QT6 production line with us in February,2022.

Batcher for Main material (prepared by Client):

2.JS750 Mixer for Main Material

QGM JS750 Twin-shaft compulsory mixing system with high mixing efficiency and uniformity. Mixing blades and lining board inside mixing tank are all made of chromium and manganese alloy, with advantages of great hardness, wear-resisting, corrosion-resisting, good durability..It also have the Self-Lubricating System to help machine to realize better performance.

3. JN350 Mixer for Face Material (Especially for pavers with color pigment)

4. QT6 Automatic Block Making Machine

Designed and Made By QGM China.

Pallet size: 850x680mm

Cycle time: 15--25s per mould (depends on product type)

a. SIEMENS Motors with great performance for high vibration force;

b. Adopt Frequency Conversional Technology from Germany to guarantee stable performance for wet block conveyor and protect electrical motor from unsteady power. It can save 20-40% power by adjusting the speed and frequency of the motor, comparing with traditional motor. .

5. Stacker

Double-pallet stacking at a time, easy for transport and curing;

6. Pallet Feeder

The weight of the pallet is heavy, and it is inefficient to use the manual feeding, but the efficiency can be improved by using the pallet feeder. An automatic pallet feeder could save 2 labors.

7. Control System

a. SIEMENS electronic components, and SIEMENS PLC S7-1200;

b. Equipped with I-Cloud system for better remote after-sales support.

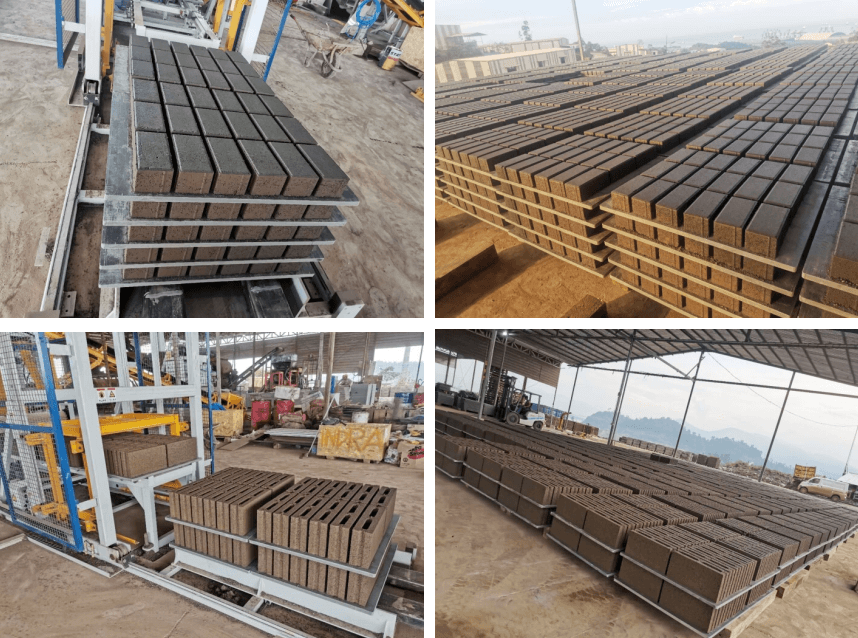

8. Finished Products