Block Moulds

QGM firmly believes that good quality stars with precision and ends with perfection. Designs and technologies from Germany and Austria also require advanced manufacturing processes. QGM has mastered sophisticated monitoring instruments and has advanced management capabilities. Its production and processing capabilities have been at the forefront of the industry for many years, from the advanced technology of Germany and Austria and the advanced manufacturing level of QGM, combined with materials, process, quality and precision from QGM mould that leading the domestic world.

-

Concrete Brick Molds for Retaining Wall

Whether it is the anchorage of slopes which serve to prevent the slipping of the soil, or the design and beautification of public areas in cities and towns or even only the herb spiral in your own garden - the applications are multifaceted, better and very simple to handle. Especially at the beginning of the planning phase, our project team will assist our customers in giving the right look to a functioning system. .

Email Details -

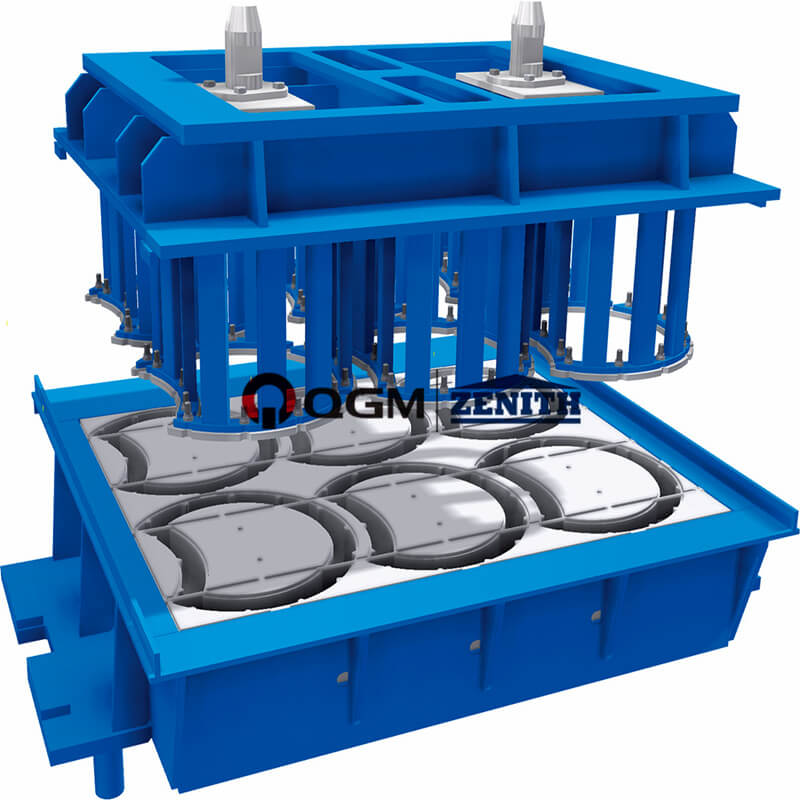

Paver Stone Moulds

QGM payer mould adopts carbunizing treatment., mould framies and pressure plates are hardened 60-63HRC, and the mirnimuim hardening depth is 1.2m.According to customers’ requests, the mould can be designed and manufactured by welding or modular thread locking..

Email Details -

Paving Stone Mold

QGM payer mould adopts carbunizing treatment., mould framies and pressure plates are hardened 60-63HRC, and the mirnimuim hardening depth is 1.2m.According to customers’ requests, the mould can be designed and manufactured by welding or modular thread locking..

Email Details -

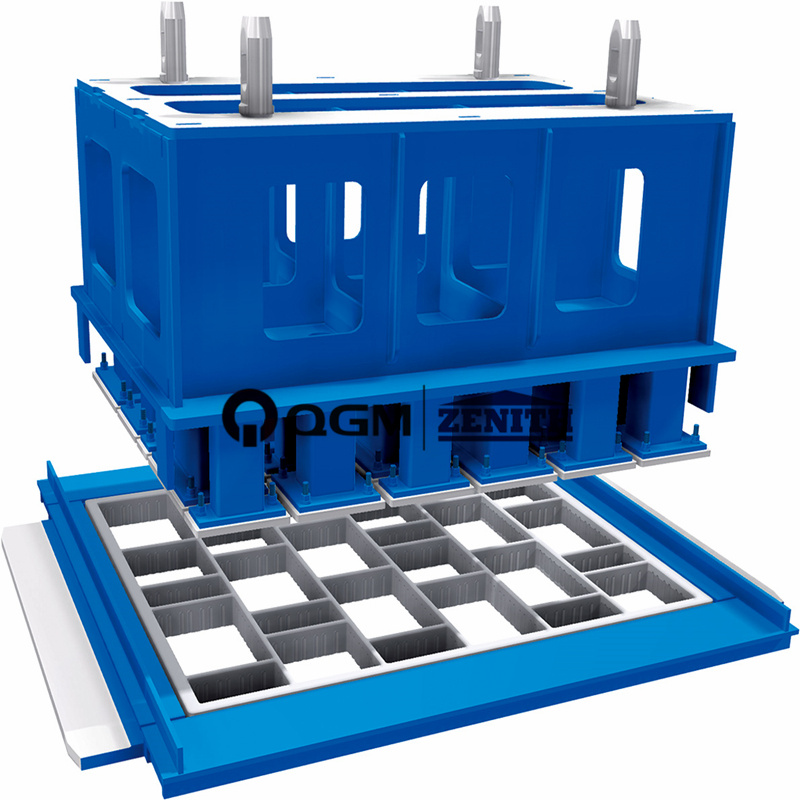

Concrete Brick Mold for Hollow Block

High quality wear resistant steel

Email Details

Robust and proven design

Optimal exploitation of the mould

Optional withdraw sheet design

Cost-effective production

Traditional and proven design -

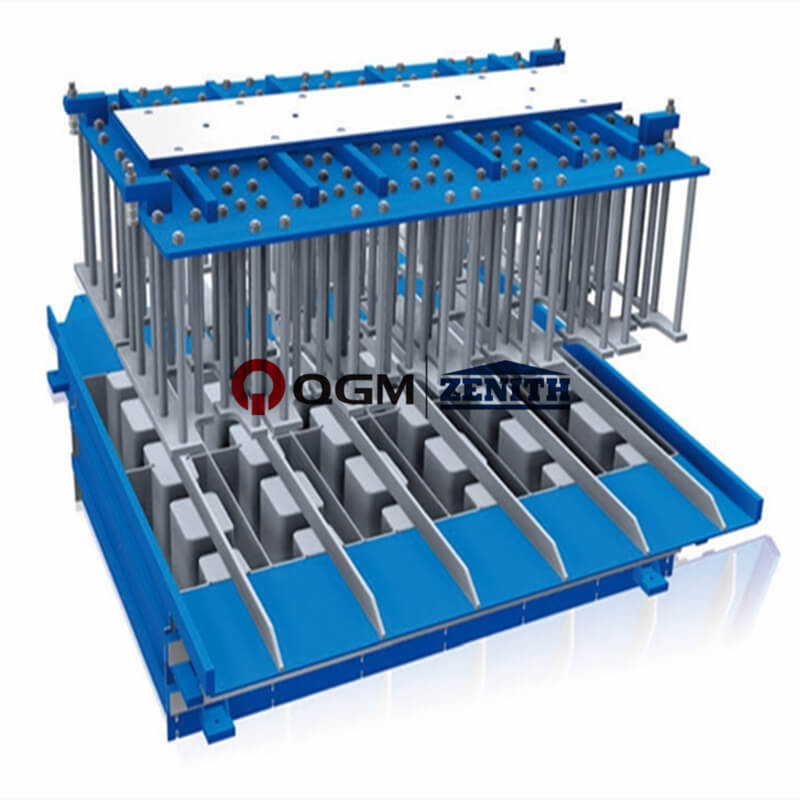

Mould for Curbstone Concrete Blocks

QGM curbstone mould adopts imported high quality wear-resistant steel, combined with great welding and processing technology,the plate adopts a special heat treatment process to ensure the wear resistance of the plate, clearance 0.5-0.6mm, the supporting web is a replaceable threaded connection design..

Email Details -

Superstructural Wood Concrete Stone Moulds

Concerning natural building materials, wood concrete certainly is the best solution in this context. Wood concrete is the “seller” today when it comes to ecology and sustainability in the building material manufacturing segment. Both are keywords that may bring a high commercial success to producers. It has the properties of mall weight, high fire protection class, breathability with extremely weathering and frost resistance characterize. ZENITH Formen has gained experience in this segment for many years; we know the production processes and are the top supplier for the corresponding moulds:

Email Details -

Fireplace Stone Moulds

The most beneficial and healthiest warmth during the cold season is provided by the traditional fireplace. Powerful fireplaces and stoves require high-quality concrete blocks. Again ZENITH Formen turns your vision into top mould shape which also benefit from our years of experience in the design and production of such systems. .

Email Details -

Concrete Tile Moulds

The production of a high quality concrete plate not only requires experience in mould manufacturing in all aspects but also implies know-how in the management and operation of modern machining center. It is a prerequisite to produce high quality concrete product and it should not be underestimated under any circumstances. ZENITH is setting here the standard in the manufacturing of concrete stone moulds.

Email Details -

Eco-Stone Moulds

The rapid draining of rainwater via sewers has led to massive groundwater problems in many regions. Eco-stone systems have achieved great success in this regard. Together with you, we at ZENITH Formen bring these often complicated systems in top-mould-shape...

Email Details