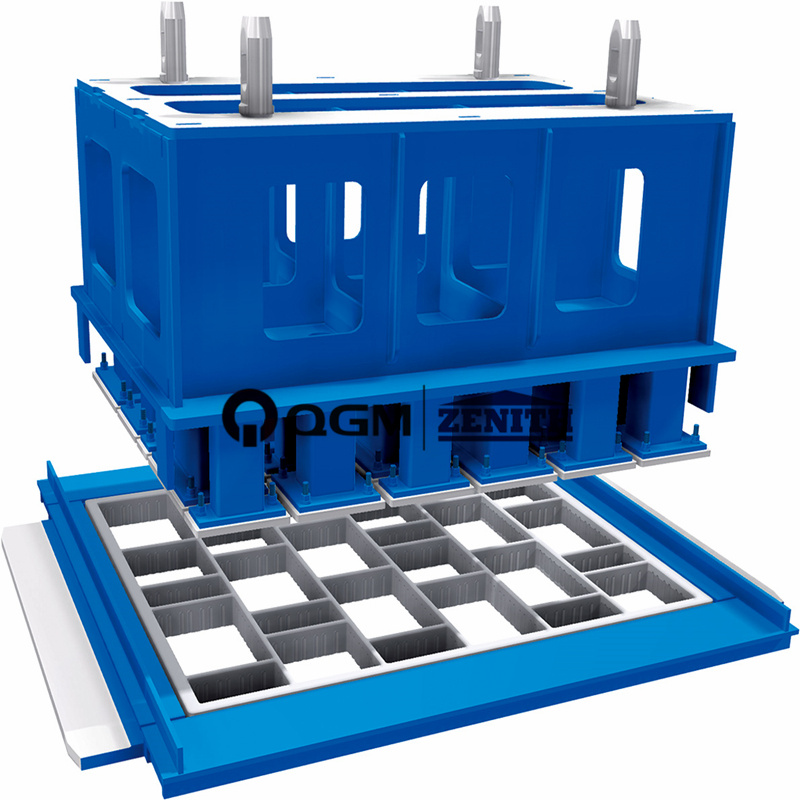

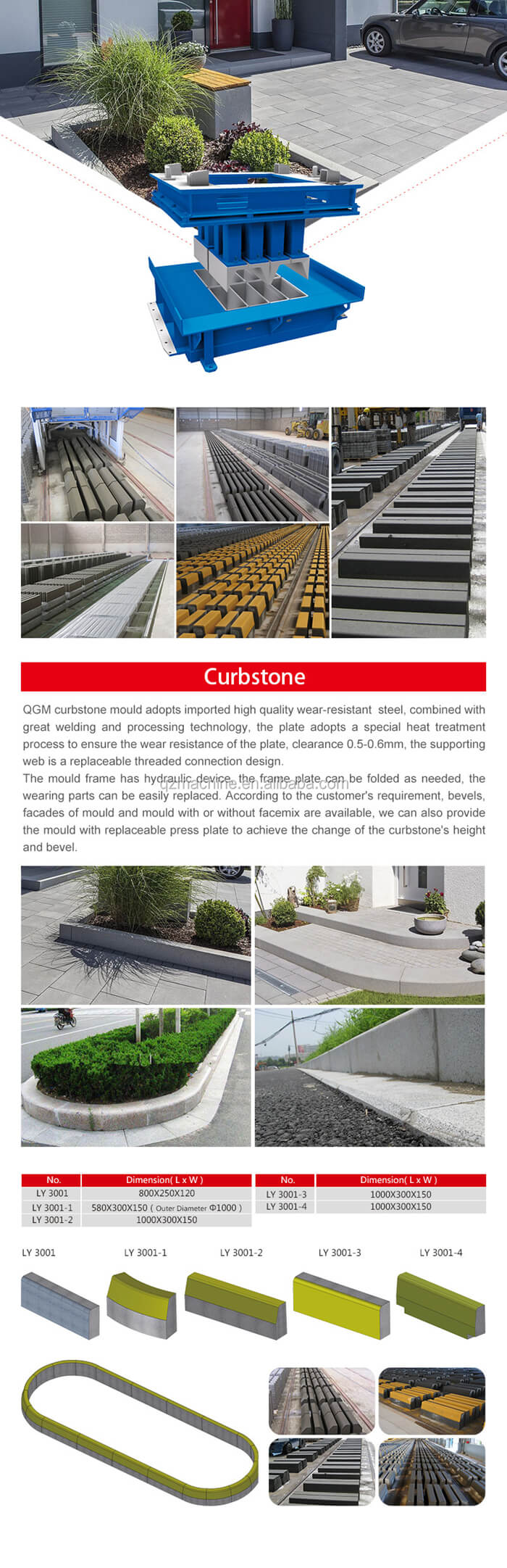

Mould for Curbstone Concrete Blocks

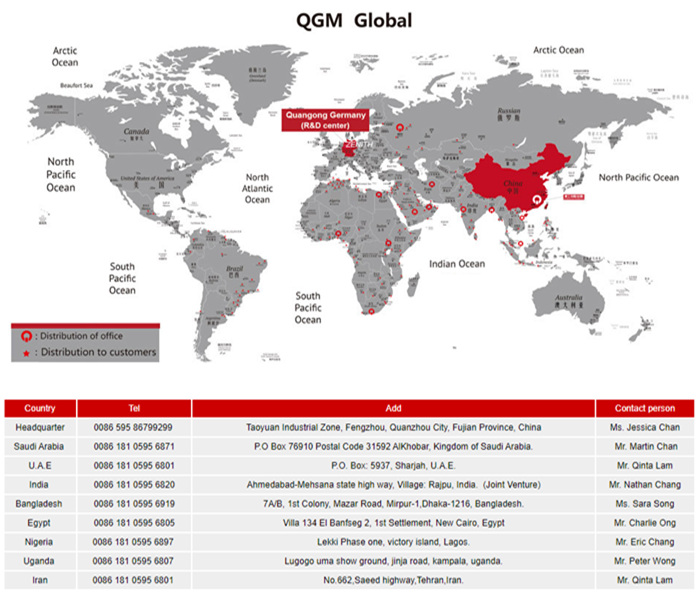

- QGM ZENITH

- China / Austria

- 30-60 days

- 1 sets per month

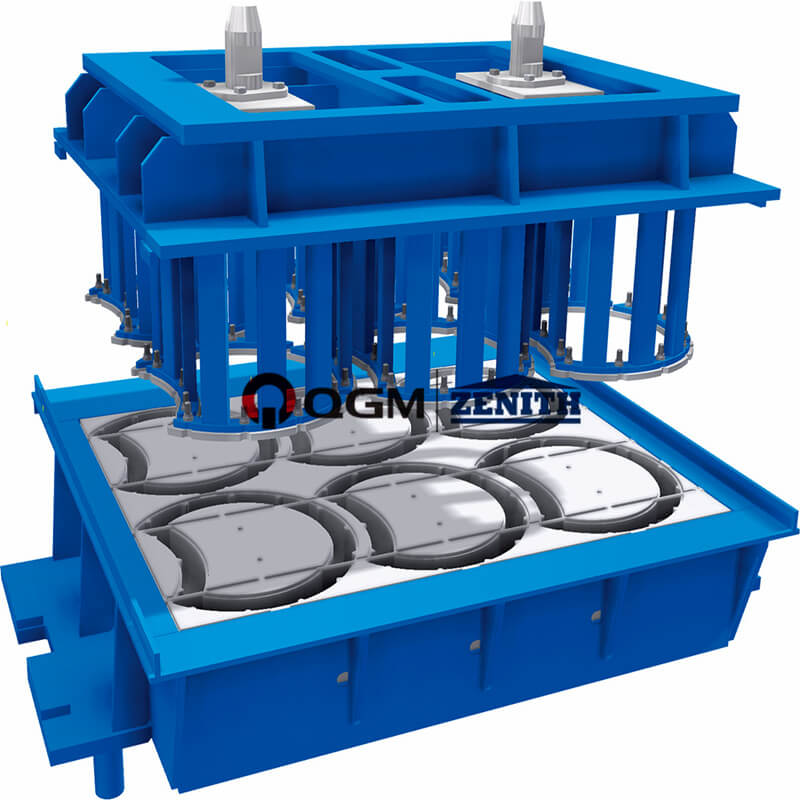

QGM curbstone mould adopts imported high quality wear-resistant steel, combined with great welding and processing technology,the plate adopts a special heat treatment process to ensure the wear resistance of the plate, clearance 0.5-0.6mm, the supporting web is a replaceable threaded connection design..

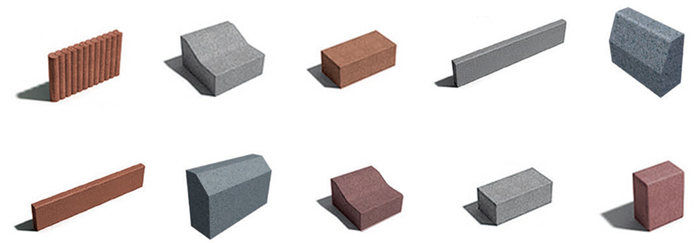

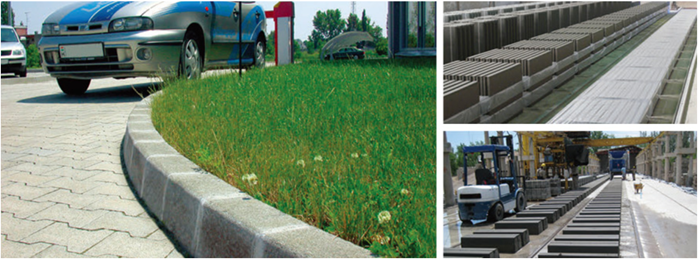

For the benefit of our customers, we have acquired an extensive know-how in the field of curbstone moulds, in various designs, slope or facade, with or without face layer, replaceable shoe to change the height and facade of curbstone, which always adapted to the corresponding facilities of our customers:

MOULD DESIGN WELDED

Combination of welded and milled design

High quality wear resistant steel

Shoe clearance 0,5 mm

Holding web thicknesses screwed and therefore changeable

Robust and proven design

Optimal exploitation of the mould

Counter-conical side walls feasible

Optional withdraw sheet design

Cost-effective production

Hydraulic folding wall elements feasible

Flexible design of mould

Easy replacement of wearing parts