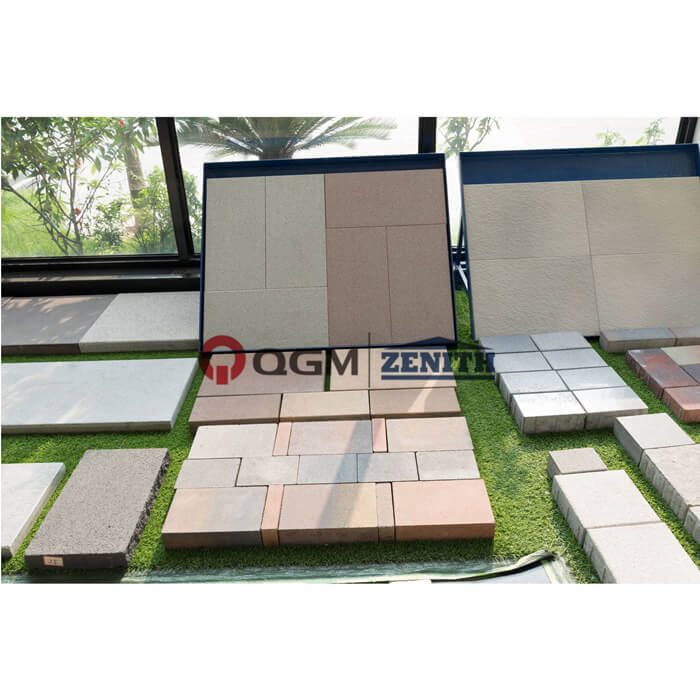

Concrete Tile Moulds

- QGM ZENITH

- China / Austria

- 30-60 days

- 1 sets per month

The production of a high quality concrete plate not only requires experience in mould manufacturing in all aspects but also implies know-how in the management and operation of modern machining center. It is a prerequisite to produce high quality concrete product and it should not be underestimated under any circumstances. ZENITH is setting here the standard in the manufacturing of concrete stone moulds.

The production of a high quality concrete plate not only requires experience in mould manufacturing in all aspects but also implies know-how in the management and operation of modern machining center. It is a prerequisite to produce high quality concrete product and it should not be underestimated under any circumstances. ZENITH is setting here the standard in the manufacturing of concrete stone moulds.

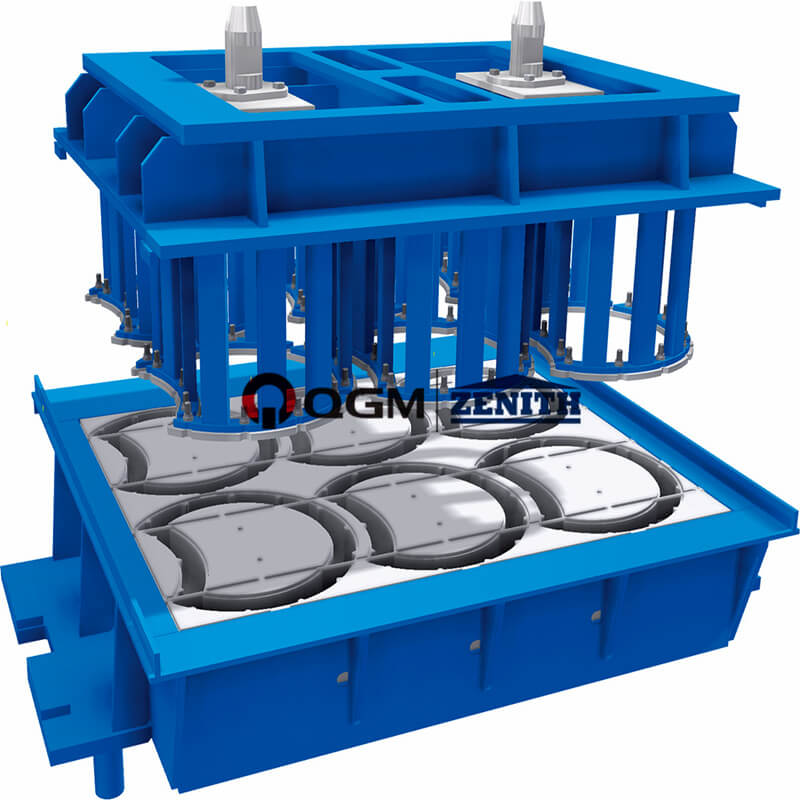

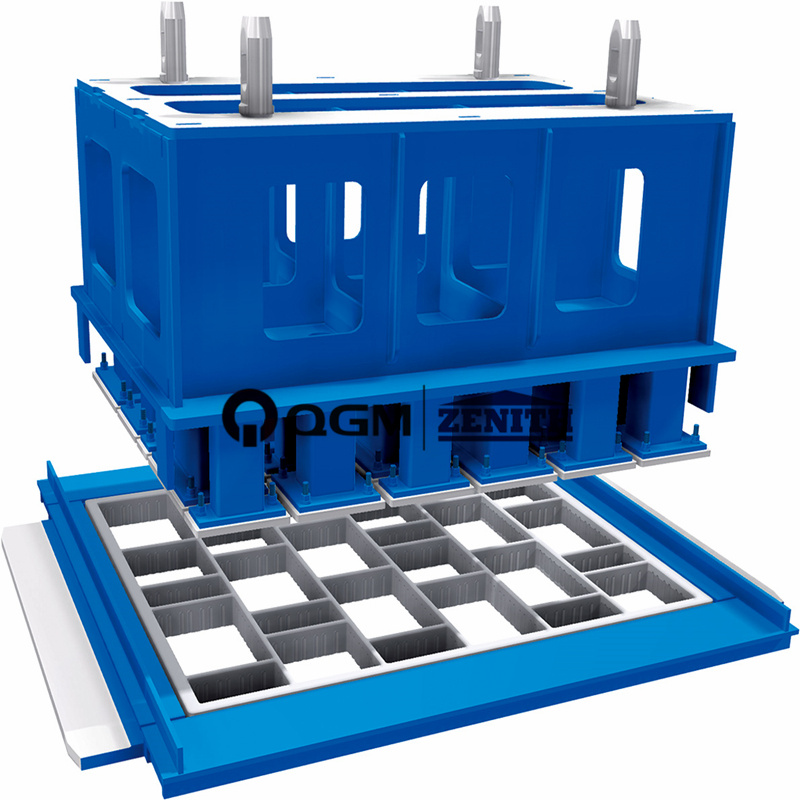

MOULD DESIGN

Combination of welded and milled design

High quality wear resistant steel

Shoe clearance 0,5 mm

Shoes easily changeable

Exchange moulds feasible

Easy replacement of wearing parts

Interior parts feasible in nitrated (62-68 HRC) version

We always determine the exact mould design in close cooperation with the customer. When concrete product comes to a low stone height of less than 50mm, we might recommend the consultation of the machinery manufacturer.