QGM QT10 Cement Brick Machine Production Line in East Java, Indonesia 2022

Background:

This brick making project is located in East Java, Indonesia. Due to the booming demand for paving blocks from the market, the client chose QGM QT10 Automatic brick making machine with a central control system from QGM this year, and the machine has started production in October, 2022.

1. Silo (Prepared by Client)

QGM could provide the silo accessory to match the silo that is prepared by the client.

2.Batcher for Main material: 3*4m³

We use weighing bin with weighing sensor to get exactly weight of raw material, so the block recipe accuracy could be guaranteed.Weighing bin with weighing sensors for the accurate recipe.

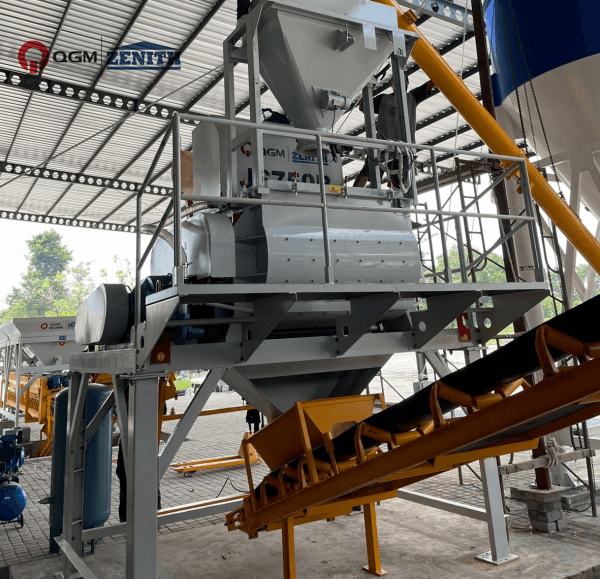

3. JS750 Mixer for Main Material

Cement weighing system with weighing sensors are installed in the mixer system for accurate recipe.

QGM JS750 Twin-shaft compulsory mixing system with high mixing efficiency and uniformity. Mixing blades and lining board inside mixing tank are all made of chromium and manganese alloy, with advantages of great hardness, wear-resisting, corrosion-resisting, good durability, which also have the Self-Lubricating System to help machine to realize better performance.

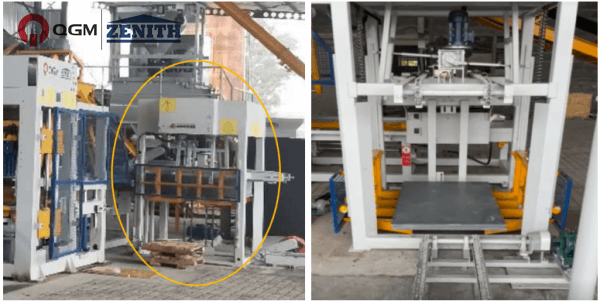

4. QT10 Concrete Brick Making Machine

Designed and Made by QGM China.

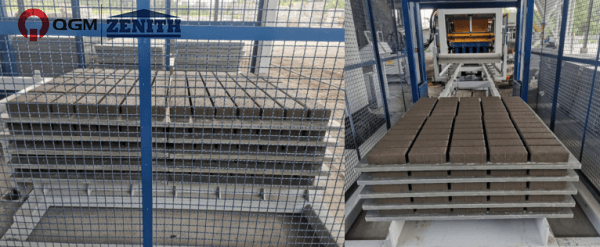

Pallet size: 1250x850mm

Cycle time: 15—25S per mould (depends on product type)

Vibration System:We use frequency control for vibration, which provide higher vibration force and adjust vibration frequency from 40-60HZ. In this way, the quality of concrete products could be guaranteed.

5. Stacker (Double pallets per layer) :Double-pallet stacking at a time, increase the efficiency.

6. Pallet Feeder: The automatic pallet feeder could save at least 2 labors.

7. Finished Products