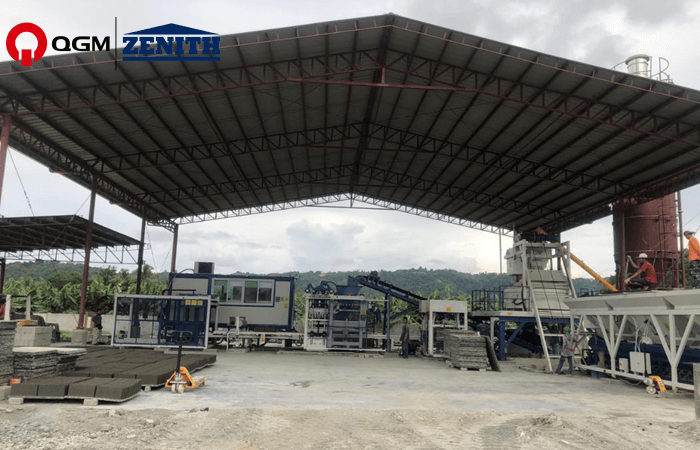

QGM ZN1000C Hollow Blocks Maker in Davao,Philippine

(Client's factory)

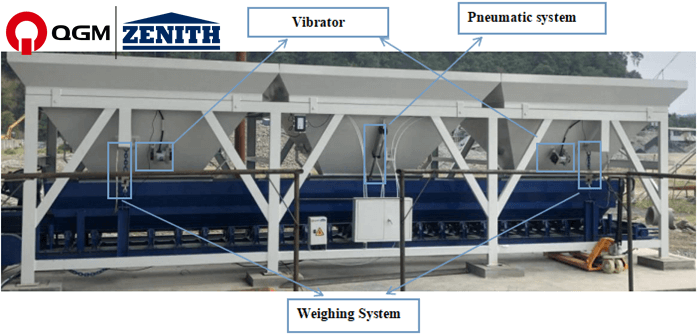

For Batcher:

Weighting sensor for calculating the exact weight of Material;

Door opened by pneumatic system;

Vibration motor on each bin for good material feeding;

Good quality Belt for sending material to mixing hopper.

Planetary Mixer MP1000: planetary mixing style, guarantees better uniform mixing, with cement weighing and water weighing system.

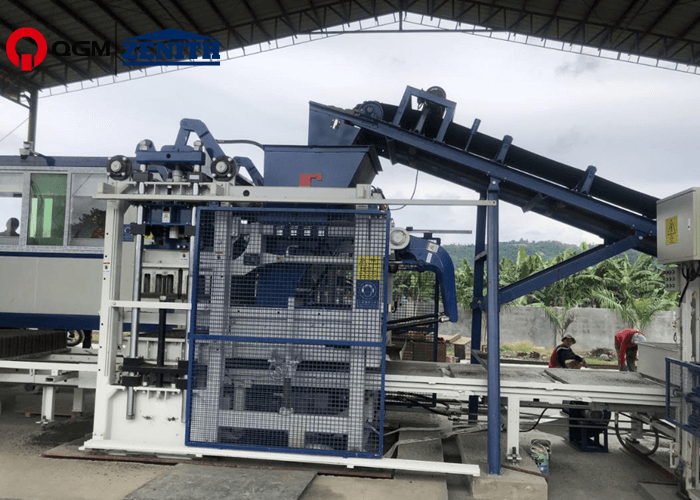

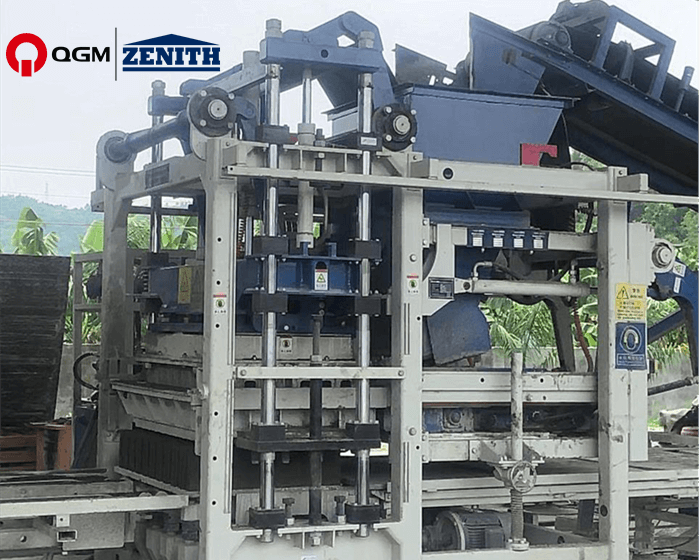

(Vibration Table-Germany Design with Dynamic table and Static table)

The Vibration System is consistency of Frequency Conversional Control Technology and System.

The vibration includes two main parts, the Bottom Vibration and the Tamper Head Vibration (top vibration). The Bottom Vibration consists of 2 Germany SIEMENS Frequency Conversional Vibration Motors. The 4 motors work separately and synchronized. It highly improves the vibration force and reduces the cycle time. The Tamper Head Vibration consists of 2 motors. With the Top Vibration, the density of high concrete products is better guaranteed and the adhesive force between mould and concrete products is reduced, which will shorten the demoulding time to reduce the total cycle time. Between the top vibration and the up-and-down cylinder, it is joined with Vibration Absorption Rubbers, which minimizes the vibration affect to mechanical system.

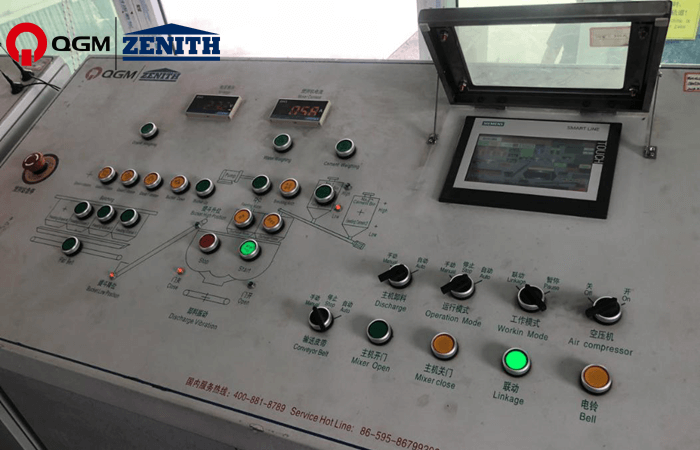

(Control Panel for ZN1000C Main Machine and Stacker with Intelligent Cloud System)

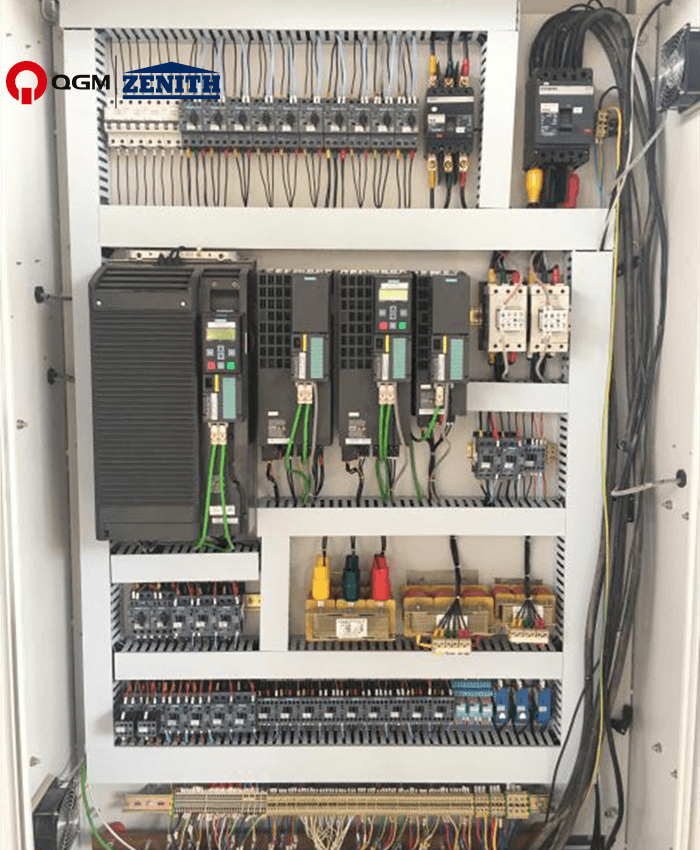

(Electrical cabinet with all electronic components from Siemens)

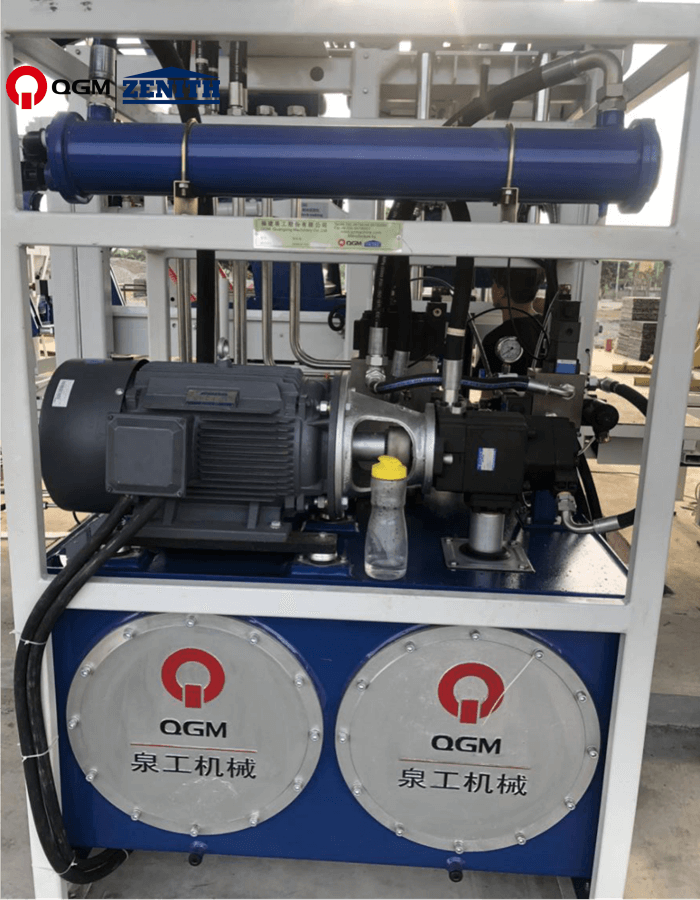

(Hydraulic Station with SIEMENS Hydraulic Motor, Italy Hydraulic Hoses)

(Stacker - two pallets per time, Frequency control)

Nature Curing-after one night curing inside, can stack outside, and curing with nature air and manual water feeding.