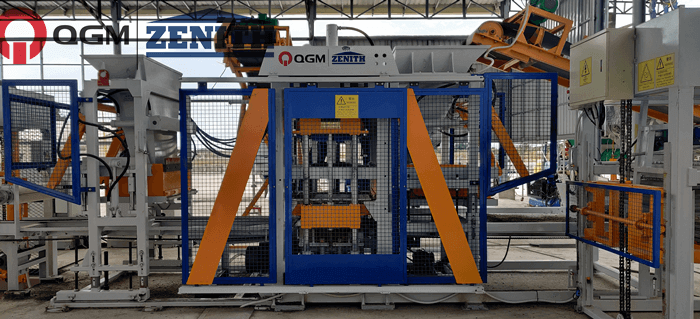

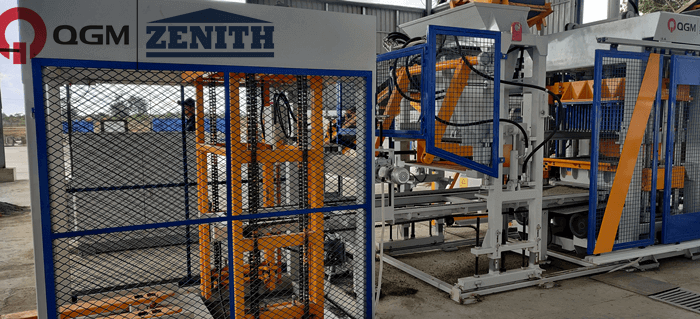

QT6 Block Molding Machine in Cambodia

Big Five Advantages Of QGM QT6 Automatic Block Making Machines:

Our machines, with harmonic cooperation between mechanical, electrical and hydraulic machines functions,guarantee a reliable and high output production of concrete products.

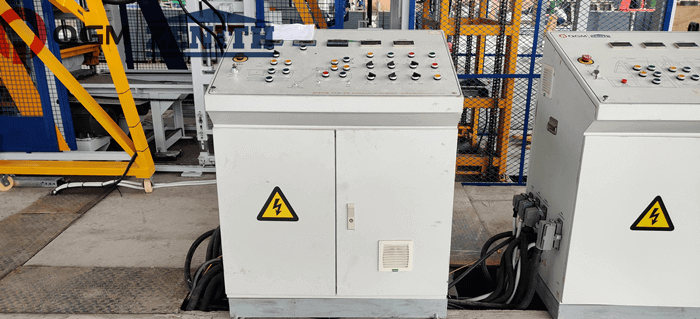

1. Use Germany Siemens Plc control system and Siemens Touch Screen, use Schneider

and Omron relays and contactors:

A. Siemens PLC, with great adaptability, guarantees the stability and reliability of the machine;

B. Visualization touch screen, with easy operation;

C. High-quality electrical components from Schneider and Omron;

2. Use Frequency Conversional Control Technology, which controls the block making:

A. Frequency Conversion Control: Guarantees the precise and parallel movement between tamper head and mould, protects the products from transfiguration; increases the production rate by improving the vibrating efficiency;

B. Controls the instantaneous start and stop of the motors, to protect the motor from over-heating caused by constant working;

C. Power saving: 30%;

3. Use Double high-dynamic Proportional/Directional Valves to automatically adjust the oil flow and pressure

A. Buffer the hydraulic cylinder, to protect the cylinder from damage caused by inertia;

B. Guarantee production stability;

4. 360°Multi-Shaft Rotating and Compulsory Feeding:

A. Speedy and rotating feeding, with Uniform mixing, to make sure that the density and intensity of the products are guaranteed

B. This uniform feeding is applicable for different kinds of raw materials and mould;

5. Use heat treatment on mould and main parts of the machines;

A. Heavy duty machine structure and wear resistant mould;

B. The hardness reaches up to HRC 52-58;

C. Greatly improves the using lifetime of the machine by 50%.

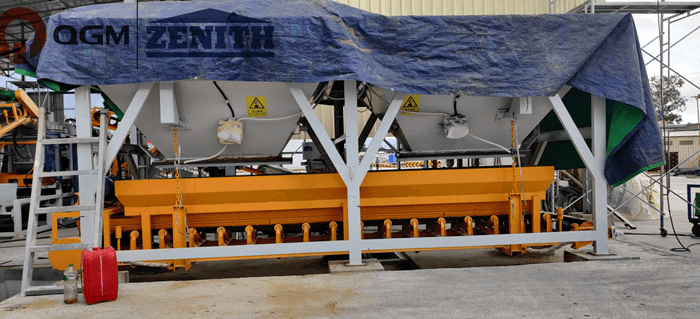

(Raw Materials)

The raw material for block making can be sand, stand dust, slag, coal gangue, fly ash and construction wastes.

(Pneumatic System(From German brand AirTac) to control the opening and closing of the discharging gate)

The client can choose two-bin to six-bin batcher according to the variety of local material. Several materials are scaled and weighed automatically as per certain ratio, which can guarantee the block quality and save cost.

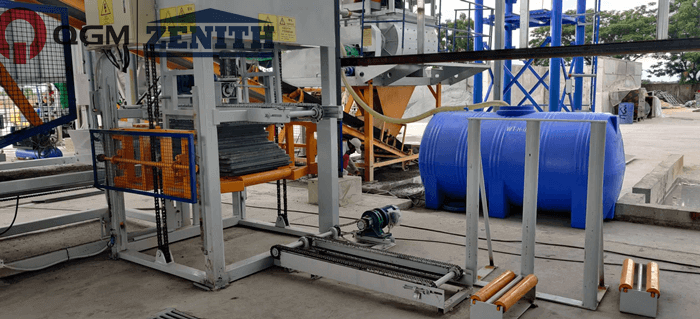

(Silo for cement storage;Mixer for the base material)

After batching, the material are delivered to the mixer. After mixing with certain amount cement and water, the materials are transported to the hopper of main machine belt conveyor.

The weight of the pallet is heavy, and it is inefficient to use the manual feeding, but the efficiency can be improved by using the pallet feeder. An automatic pallet feeder could save 2 labors.

The control system adopt Germany SIEMENS programmable logical controlled, which is easy operation and low failure rates. Most of electronic components adopt SIEMENS brand.

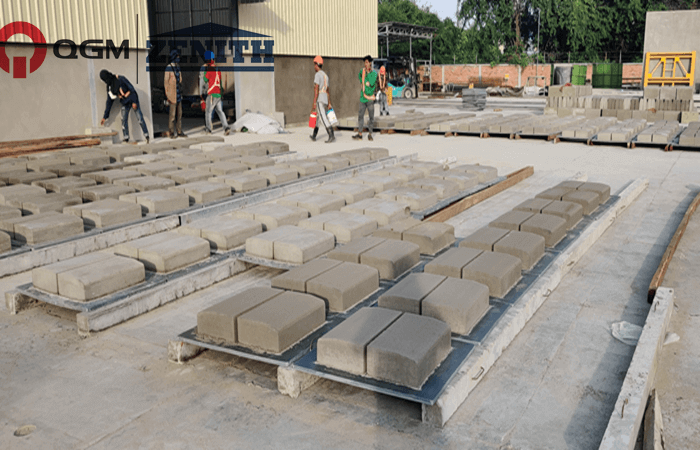

(Stacker:One pallet at a time, easy for transport and curing.)

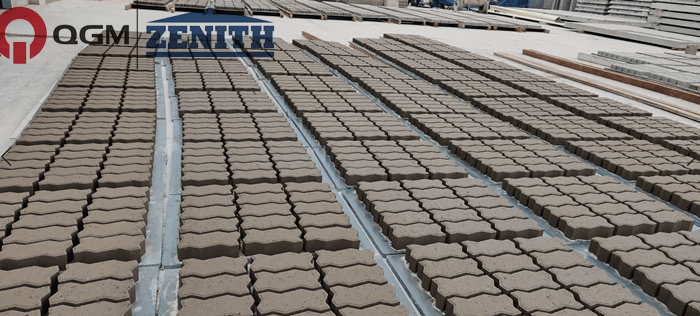

Finished products:

Under the COVID-19, to reduce the installation cost for the client, QGM engineer guided the client's engineer to install and commission the QT6 machine. Benefiting from easy operation of Siemens control system, the machine is running properly.