ZN1000C Block Making Machine in Colombia

(Client's factory)

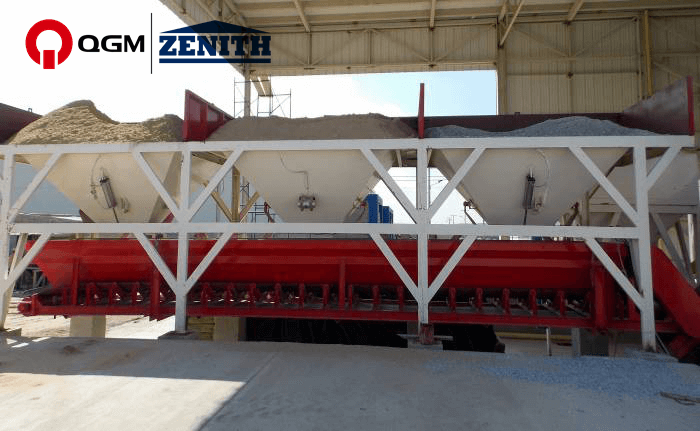

(3-bin batcher for main materials, 1-bin batcher for facemix material, and V-belt conveyor)

Through scale hopper, batcher is used to measure the accurate weight of aggregates (stone and sand) automatically, with high precision and accuracy.

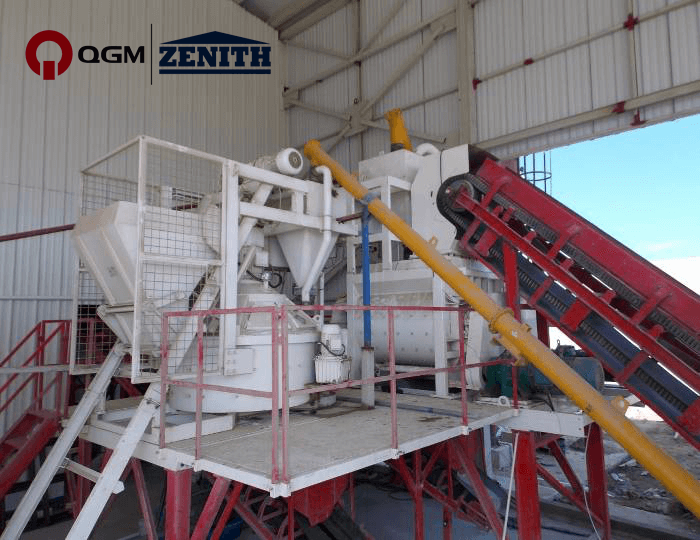

(Mixer for main materials: JS1000)

Horizontal twin-shaft compulsory mixer has the strong mixing ability with uniform mixing and high production output. The admixtures are widely mixed by the shafts, and reached the excellent proportional ratio of uniform in short time.

Mixing paddles, arms and blades are made of special high chromium and manganese alloy materials. The wear resistance of the mixing paddles saves time and cost to replace, and at the same time, improves the machine’s durability and reliability.

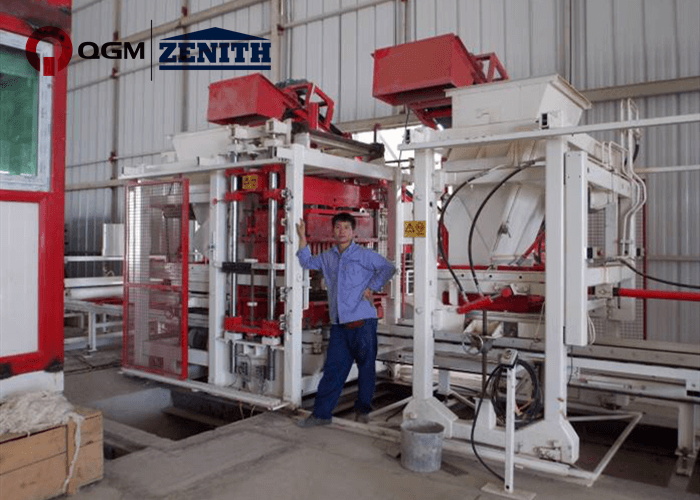

(ZN1000C Block Making Machine with Facemix Device)

Technical Parameters

1. Production Area:1100x820mm

2. Block Height:50~300mm

3. Pallet Dimension:1,200x870x45 (Wood); 1,200x870x12(Steel)

4. Cycle time:15-25s(Depending on Product Type)

5. Volume of Hoppers:Main Material: 900L ; Face Material: 750L

6. Hydraulic Motor: SIEMENS, 22kW

7. Main Hydraulic Pump:Italy VOTZ

8. Hydraulic Valve:Italy VOTZ

9. Oil Cooling Device:1x0.75kW

10. Vibration Table:SIEMENS, 2x7.5kW(Standard)

11. Top Vibration Motor:OLI-WOLONG, 2x0.65kW

12. Frequency Converter: SIEMENS

13.Electrical Components:SIEMENS/TURCK/Schneider/PILZ

(Triangle Belt Conveyor for Green Products)

"Soft connection" between belt and pallets. Triangle belt conveyor guarantees stable and smooth conveying of wet blocks. The "soft connection" between belt and pallets avoid the damage of fresh wet blocks.

Frequency conversional control. The triangle belt is driven by Frequency Conversional Motor, which controls the speed of conveyor. Therefore, impact and damage of wet blocks due to the force of inertia can be avoided.

Automatic grouping of pallets. When two pallets of wet blocks reach to the right position of elevator, they group as one layer and then the elevator will automatically elevate one layer.

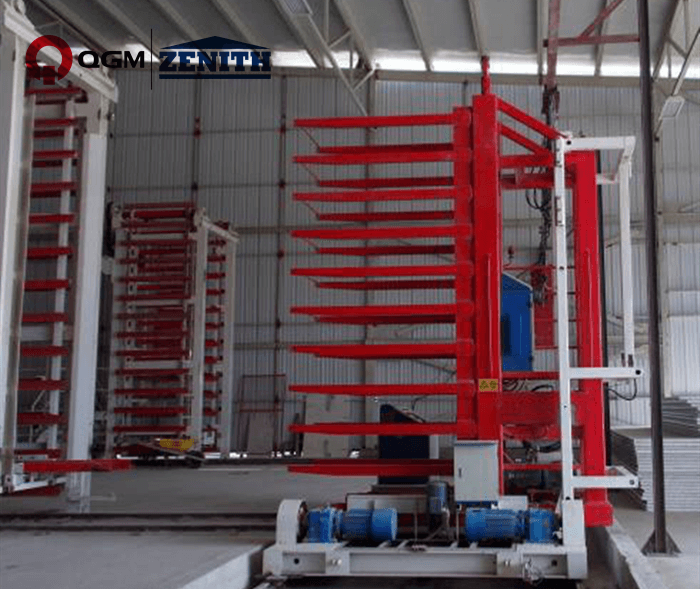

(Elevator and Lowerator)

QGM Elevator and Lowerator have following features:

· Adopting FV112 (Pitch=100mm) heavy-duty lifting chains, with high-load capacity. The lifting chains are international standard, and interchangeable.

· Synchronization Device. Compulsory synchronization device is used during the high-speed stage, providing precise synchronization and small moment of force.

· Gear Motors are German SEW motors.

· Automatic Centering Device. If there is a slight tilt of pallet (within the allowable range), the pallet can be automatically centered.

· Automatic pallet separating system. Two pallets of blocks (one the same layer) are lowered and laid on conveyor for dry blocks at different height. Then these two pallets are automatically separated. This design avoids two pallets sticking together when they are conveyed out of lowerator.

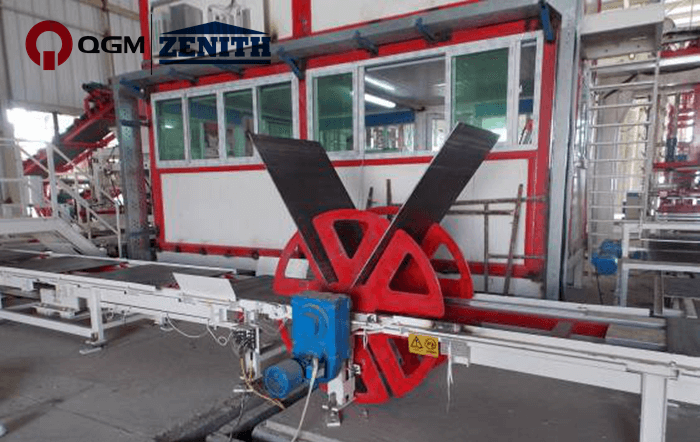

(Finger Car)

(Transfer car)

· Large load capacity. The load capacity of the crawler is up to 16T.

· High speed. The speed of the transfer car is up to 0.75m/s.

· Auto and Manual control mode. Auto and Manual control mode can be switched over at any time based on practical situation.

· Upper guide system of transfer car. It guarantees the precise movement by wheel compulsory centering.

· Frequency conversional control. The speed of transfer car can be controlled by SEW Frequency Conversional Motor. Therefore, impact and damage of blocks due to the force of inertia can be avoided.

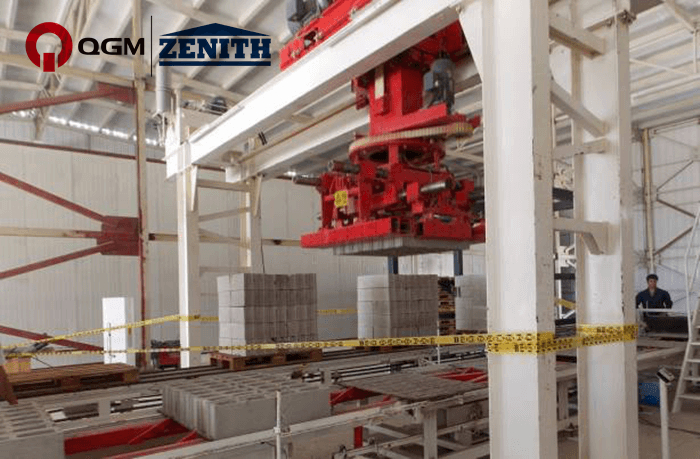

(Stacker)

The Stacker can be divided into four parts, from the structure and function: Horizontal moving device, vertical moving device, rotating device and clamping device. The horizontal, vertical and rotating devices adopt SEW frequency conversional motors. Clamping device uses hydraulic system to achieve the requirements. The movement position of the horizontal, vertical and rotating devices are inducted by approach switches, and controlled by PLC.

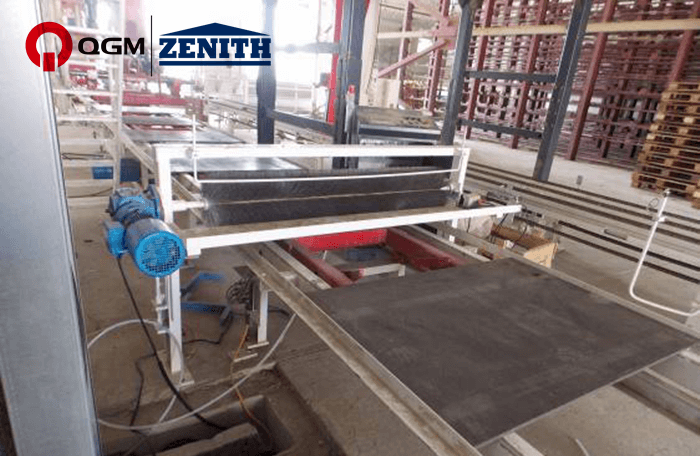

(Lengthways Latch Conveyor with pallet cleaner)

(Transverse Latch Conveyor with Pallet Turner)

The Lengthways and Transverse Latch conveyors have following technical features

· Frequency conversional control. The speed of latch conveyors can be controlled by Frequency Conversional Motor. Therefore, impact and damage of finished blocks due to the force of inertia can be avoided.

· Modularized and Standardized "Pushing Blocks". All the "pushing blocks" used in lengthways and transverse latch conveyors are modularized, standardized and interchangeable.

· Heavy-duty chain wheel drive. Use international standard and interchangeable chain; Connected with frequency converter, which guarantees the smooth and stable conveying, and provides large moment of force.

· The latch conveyor consists of "fixed frame" and "movable frame". It has strong structural strength and provides powerful conveying force.

· Wear-resistant plates adopt HARDOX steel, which is durable and reliable.

· Heavy-duty chain wheel drive. Use international standard and interchangeable chain; Connected with frequency converter, which guarantees the smooth and stable conveying, and provides large moment of force.

(Heavy-duty chain controlled by frequency conversional motors)

(Packing System)

All the electronic equipment, such as control panels, computers and electronic cabinets are in the control room. Therefore, the electronic components are prevented from dusts and high humidity, which are very bad for electronic components.

The control room is equipped with air conditioner, which provides comfortable and consistent temperature. This environment helps extend the working life of electronic components.

During the normal production, operators just need to stay in control room to control the machine. The control room prevents the operators from dust, noise and high temperature. It makes operators work more efficiently.

T10 block making machine can produce concrete blocks, solid/hollow blocks, pavers with or without color on the surface, garden and landscaping products, slabs, curbstones, interlocking blocks, etc. Here are some samples: