Steerable concrete block machine needing no rails for Dirksen Sierbeton

The Dutch concrete block manufacturer Dirksen Sierbeton approached Zenith Maschinenfabrik in the middle of 2018 with a very special request. The company was interested in a version of the travelling Zenith 940 S&C concrete block machine that needed no rails.

Dirksen Sierbeton operates a total of three concrete block machines and covers a wide range of differing products for house and garden construction work as well as landscaping. Its product portfolio covers standard products through special niche products right up to custom-made designs.

In the course of renewal investment, one of their machines was to be replaced by the travellingZenith 940 S&C concrete block machine with its very diverse production capabilities. The regular version of this travelling machine runs on rails. A version running independently of rails was needed to maintain the existing infrastructure and save on expensive modification work.

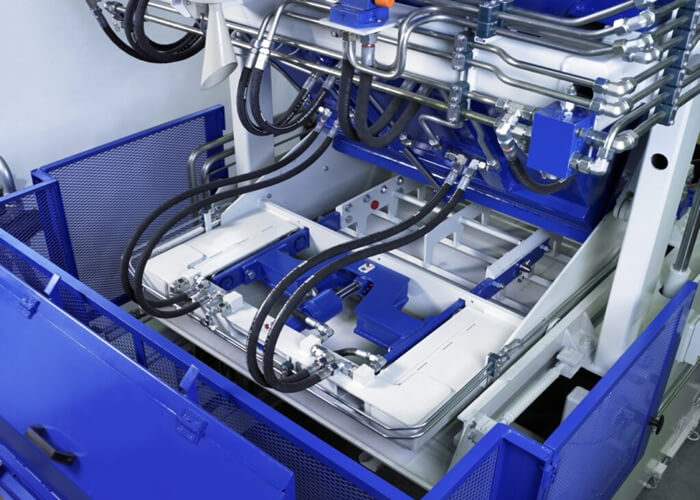

Zenith's engineers rose to the challenge and successfully designed the first steerable Zenith 940 S&C that does not run on rails. In view of the large bearing load, the greatest challenge in designing the new machine was to engineer a steering system with drive unit. The steering and drive units are fitted with Rexroth proportional valves with proportional control. Added to this, the machine features high performance drive motors from Danfoss.

The machine possesses hydraulic single wheel drives without synchronisation but with a brake fitted instead of an additional brake.

One further custom-made feature from Zenith is employed in order to guarantee that the machine can be steered precisely. The inner wheel was equipped with a greater steerage leeway of +- 45 degrees. This allows the machine to be manoeuvred even in very tight spaces.

Since the former steel rollers could not be utilised, the challenge also involved designing suitable wheels which could withstand the enormous load. In this case, special Vulkollan wheels with an enlarged diameter were used. These do not damage the ground and can at the same time cope with the huge load of over six tonnes.

This newly designed version of the Zenith 940 S&C can be employed in manufacturing single layers of products from 40 mm right up to 1,000 mm in height.

Concrete is fed into the machine at Dirksen Sierbeton by means of a forklift with a concrete silo. Alternatively, a fully automated concrete supply is also possible using a bridge feed unit.

A modification to the programme is planned as the next step in order to install facing concrete manually. A light curtain will be employed to guarantee maximum occupational safety.

Laser technology with wall distance measurement ensures that the machine remains on track even without guiderails. The distance to blocks already produced is measured by ultrasound as well to exclude damaging any of them.

Since the newly developed machine does not run on rails, savings can be made on the substantial investment costs for rails. The rail assembly work is also eliminated as is the transfer carriage for transporting the machine from one track to the next.

Its custom-made width with an additional 80 mm means that existing moulds can be reutilised.

One crucial factor in deciding for a machine needing no rails was the elimination of modification work. The production hall was already standing and the existing infrastructure could be reutilised unproblematically.

The customer is especially impressed by the fact that production output has doubled with the new Zenith machine as compared with before.

(Article published in:www.cpi-worldwide.com)