Offline Block Cubing System

- QGM ZENITH

- China

- 45-90 days

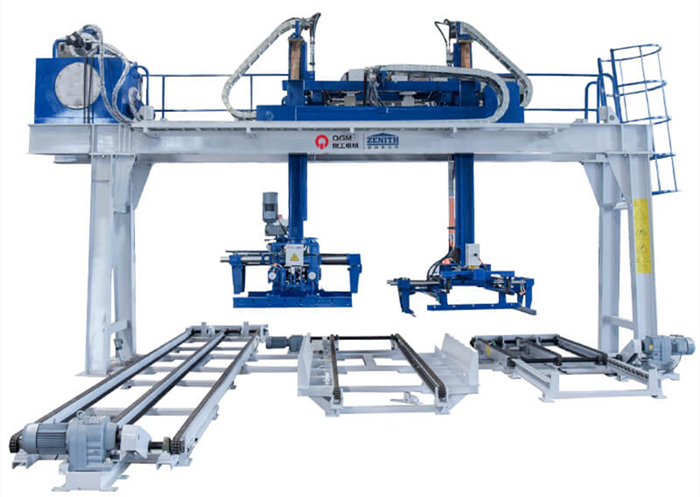

At present, most customers use simple block production line and cube bricks manually, which not only need large labor force with low production efficiency, but also is not conducive to the standardized and safe production management in the factory. For the disadvantages of palletizing in simple block production line, QGM independently developed the block-pallet separator, which can be installed near the block curing chamber to palletize the semi-finished bricks and realize automatic block pallet separation, which mainly consists of block cubing device, cuber, walking system, lifting system, conveying system, hydraulic system and intelligent control system.

At present, most customers use simple block production line and cube bricks manually, which not only need large labor force with low production efficiency, but also is not conducive to the standardized and safe production management in the factory. For the disadvantages of palletizing in simple block production line, QGM independently developed the block-pallet separator, which can be installed near the block curing chamber to palletize the semi-finished bricks and realize automatic block pallet separation, which mainly consists of block cubing device, cuber, walking system, lifting system, conveying system, hydraulic system and intelligent control system.

Main features:

2) Two pallet of blocks can be clamped at a time, and the clamp device can be rotated 90° to cross-palletize into square pallets.

3) It can reduce 5-6 labors and lowing the labor cost.

4) Stable and convenient automatic operating system (SIEMENS PLC control), greatly improving cubing efficiency.

5) Efficient and stable block clamping system, avoiding manual cubing of clamping blocks, greatly reducing the breakage rate.

6) Adopt pallet recycling device, neat and efficient, convenient for forklift to transport to automatic pallet feeding machine for reuse.

7) Mechanical cubing, convenient for plant safety production management. Technical parameters of brick pallet separator.

Technical parameters

| Overall machine dimensions | 7850×6500×5100mm |

| Pallet 1350 directional cubing size range | 730-1400mm |

| Pallet 1400 direction (two pallets) cubing size rrange | 670-1450mm |

| Traveling | 2.2KW (Pallet conveying) |

| 2.2KW (Pallet conveying) | |

| 1.5KW (Brick pallet conveying) | |

| Motor power for pallet cleaning device | 0.55KW |

| Weight | 10.5T |

| Cubing height | 1100mm |

| Motor power of hydraulic station | 22KW |

| Rotation oil cylinder | 90° |

| Cubing chain conveyor | 2.2KW |