Demand for Automatic Block Machine Surges

Nowadays, all walks of life have begun to transform and upgrade from high energy consumption and high pollution to low energy consumption and low pollution. The automatic block machine industry is no exception. Traditional sintered block production equipment is gradually declining. The annual demand for new building baking-free blocks has surged, and manufacturers of automatic block making machine will gain new opportunities for development.

The production of environmentally friendly blocks can reduce energy consumption and air pollution. The traditional clay block making process requires soil and sintering to make blocks, which destroys and occupies a lot of land resources. According to relevant data, the production of solid clay blocks requires about 50000hm2 (750000mu) of land each year. Coal sintering process not only wastes coal resources, but also causes a large amount of sulfur dioxide, carbon dioxide emissions and dust pollution, which easily damage environmental. Therefore, the transformation of traditional clay blocks to environmental protection is one of the effective ways to reduce pollution and save energy.

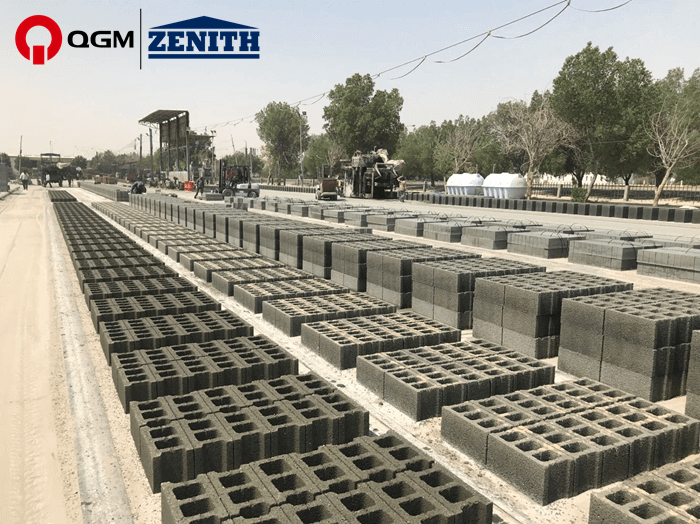

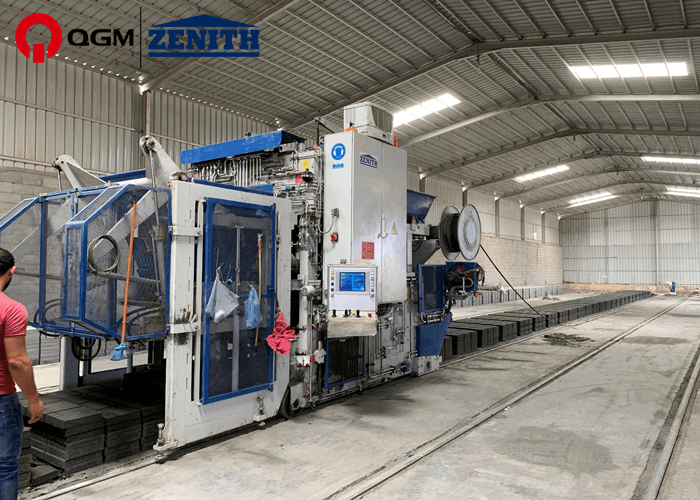

The baking-free blocks do not need to be sintered. And it can be made of various waste materials, waste residues and other waste resources, which not only saves energy and eliminates coal pollution, but also realizes the recycling and reuse of waste resources. The fully automatic CLC block machine developed and produced by QGM has good block making effect, high strength and neat appearance. It is widely used for block making from construction waste, coal ash, stone powder, tailings, slag, water granulated slag, gangue and other waste residues.

It is a revolution that the automatic block machine replaces the clay block machine, and it is the necessity of people’s survival and sustainable development. Nowadays, more and more investors are visiting QGM block machine factory and throwing olive branches of in-depth cooperation.